LGP Sheet: History, Present and Its Science

Points covered in this article

- Introduction

- Where it all started

- Development of LGP Sheet

- Science behind LGP

- Application of LGP

- Conclusion

Read Time

5 Minutes

Introduction

LGP sheets also known as Light Guide Panel sheets came in demand in the early 20th century. LGP (Light Guide Panel) sheets are a special type of plastic sheet that are designed for edge-lit applications. They are used in many industries for lighting, signage, and displays.

WHERE IT ALL STARTED

1. Cold Cathode Fluorescent Lamps

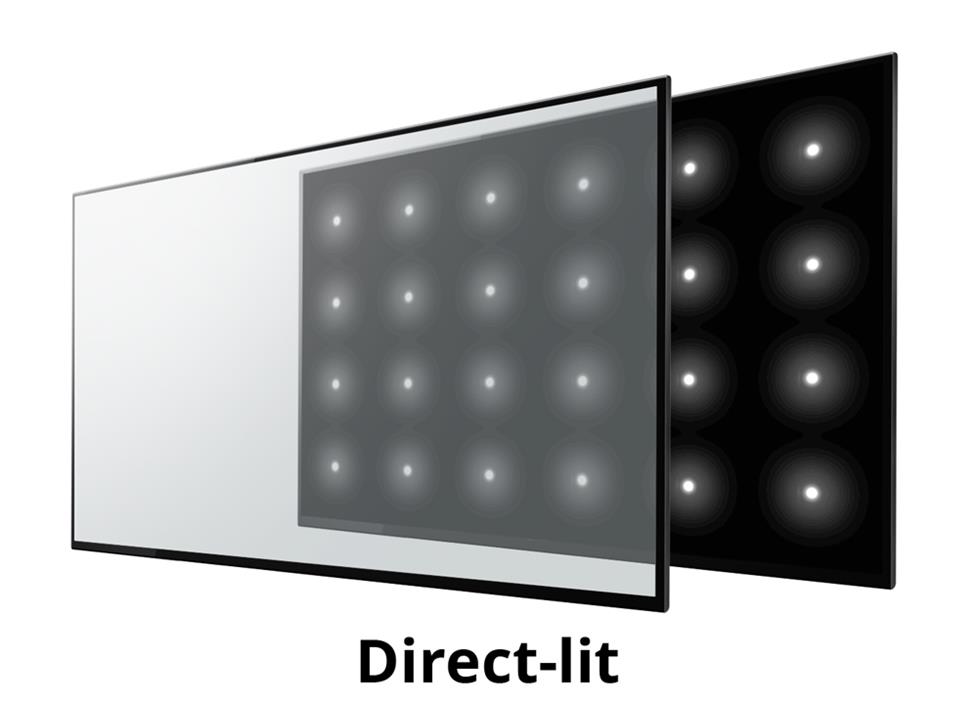

Before LGP, CCFL(Cold Cathode Fluorescent Lamps) were used. CCFLs were used as either Direct-lit or Edge-lit, for Direct-lit application the CCFL was placed directly behind the LCD (Liquid Crystal Display) Panel, although it gave good results the displays turned thick and heavy after the application.

Edge-lit application had its own demerits which were hot spots, now these spots were experienced where uniform light distribution across a larger area was needed.

CCFLs being bulky, more energy consuming and with a shorter lifespan led to the development of Light Guide Panel Sheets.

2. Direct-Lit LED Arrays

As the LED (Light Emitting Diode) application behind LCD became popular in the market due to their low costs and efficiency, it simply replaced CCFL.

But this display also had some limitations of being thick, costly, and generation of more heat.

3. Electroluminescent Panels (ELPs)

ELP was a thin panel which phosphors emitted light when this panel was attached to an alternating current. Although ELP was thin and provided even light it require high voltage AC inverter and had short life span.

Even after having a better quality than CCFL and LED, it’s brightness was still low.

This led to the invention of Incandescent Lightbulbs.

4. Incandescent Lightbulbs

Incandescent Bulb was used for backlighting but it generated large amount of heat, were bulky and had short lifespan just like an ELP.

Development of LGP Sheet

Light Guide Panel was introduced after Incandescent Light bulbs and gained popularity due to its emergence as a crucial innovation to leverage the advantages of LEDs. Its development was done in Japan, China, Taiwan and South Korea. These countries have been a leader in production of these sheets.

Merits of LGP Sheet:

Even distribution of light over large thin area, Energy efficient screens, Less costly,

Lightweight, Long-lasting, Bright display.

Science behind the LGP Sheet

The core principle of Light Guide Panel is Total Internal Reflection. Due to it’s lightweight properties TIR is possible in LGPs because of the difference in refractive indices between the LGP material and air.

The core principle of Light Guide Panel is Total Internal Reflection. Due to it’s lightweight properties TIR is possible in LGPs because of the difference in refractive indices between the LGP material and air.

The entry angles for light are carefully designed so that the light gets trapped inside the panel sheet and bounces from surface to surface through via TIR. This is achieved through precisely engineered light extraction patterns.

Micro-Patterns/Dots: From the two sides of the Light Guide Panel Sheet one side is covered with pattern of microscopic dots or other microstructures.

These patterns are encountered by the rays. The irregular surface changes the angle of the light interaction so it is scattered and refracted outwards through the front surface of the LGP.

Since LGP Sheet is known for its uniform scattering of light, it’s patterns do not particularly have uniform size, density and shape. Patterns away from the LEDs are smaller where the light is the brightest.

As you move away from the light the patterns become denser. This non-uniform pattern ensures that the light is scattered uniformly across the surface of the sheet.

Applications of lgp

The primary usage of LGP Sheet is for displays

Electronic Gadgets

Advertisement purposes

For signages

Medical Industry

Conclusion

So if you are thinking of buying an A-grade Light Guide Panel Sheet you should always go for Acrylic LGP Sheet, we can also call it PMMA (Polymethyl Methacrylate) because it provides high clarity light transmission and good UV resistance. It also does not turn yellow very quickly and is rigid with good surface hardness.

As we finally come to the conclusion, we can see that wherever a thin and uniformly lit surface is required especially when powered by LEDs, the Light Guide Panel Sheet is a must.

Please leave a comment below if you liked our article.